TurboExpanders

At Blair Engineering, we understand that turboexpanders are critical to your plant’s operation and provide solutions with reliability and performance in mind. We offer both fully-skidded new-unit packages custom-built for your application, as well as aftermarket parts, redesign, service and support for all turboexpander brands. Our standard delivery schedules are very competitive, and if the need should arise, we also offer expedited deliveries that typically exceed what other manufacturers are able to provide. We are known for our customer-centered approach and offer world-class service and support to keep your turboexpander operating 24/7.

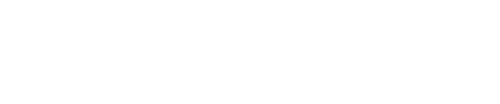

Our aftermarket experience spans all brands, including Texas Turbines Inc., Rotoflow, Mafi-Trench, LA Turbine, Gas Power Systems, Cryostar, Airco, Atlas Copco, GE, and more. At Blair Engineering, we can reverse engineer and supply turboexpander parts from any supplier and provide upgrades to bring your expander design into the 21st century. Blair Engineering provides a level of engineering support that you may not otherwise get from other original equipment manufacturer’s (OEM).

Skidded Packages

At Blair Engineering, we can manufacture skidded new-unit packages designed per our standard for non-hazardous areas such as industrial gas plants or for hazardous areas per API 610/614. Our maintenance friendly layout uses stainless steel system piping to maintain cleanliness as well as reduce the amount of time to commission the unit at site.

Aftermarket

At Blair Engineering, we have the knowledge and experience to support all brands of turbo-expanders. No matter if you need a routine repair, capitol spares, an updated control system, or a full redesign for new process conditions we can provide the support that you need. We offer expedited delivery options as well as maintaining a significant stock of parts for common machines.

Field Service

Runtime is critical, and we are acutely aware of it. With service personnel located in various US locations as well as abroad, we can typically have a service technician onsite within 24 hours. Our stock of parts for common machines also gives us the advantage versus our competitors that we will have most common parts required for basic repairs. In the event that a custom parts is required, we leverage our in-house manufacturing to perform quick turnarounds on parts, often within 48 hours.

Design

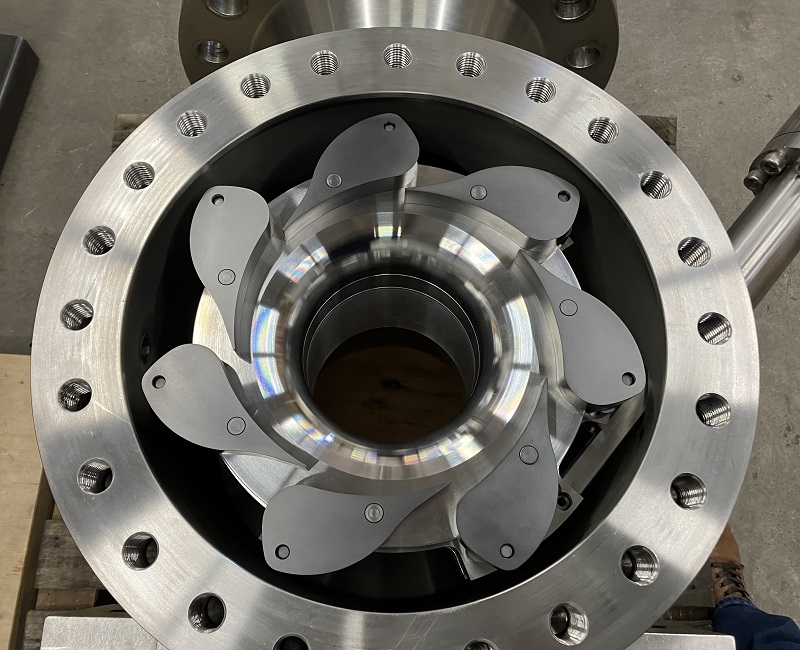

Blair Engineering's turboexpander designs are capable of operation across a wide range of speed with our stiff-shaft rotor design and robust bearing system, which is manufactured in-house. Our high efficiency compressor impeller designs are quiet in operation and offer a wide range from surge to choke. Blair Engineering's nozzle design utilizes the best features gained from our experience on multiple brands of turbo-expanders, and is a low-friction type design as standard, without sliding pins, and with double shear actuator rod connection. Anti-friction coatings provide long life on all components.