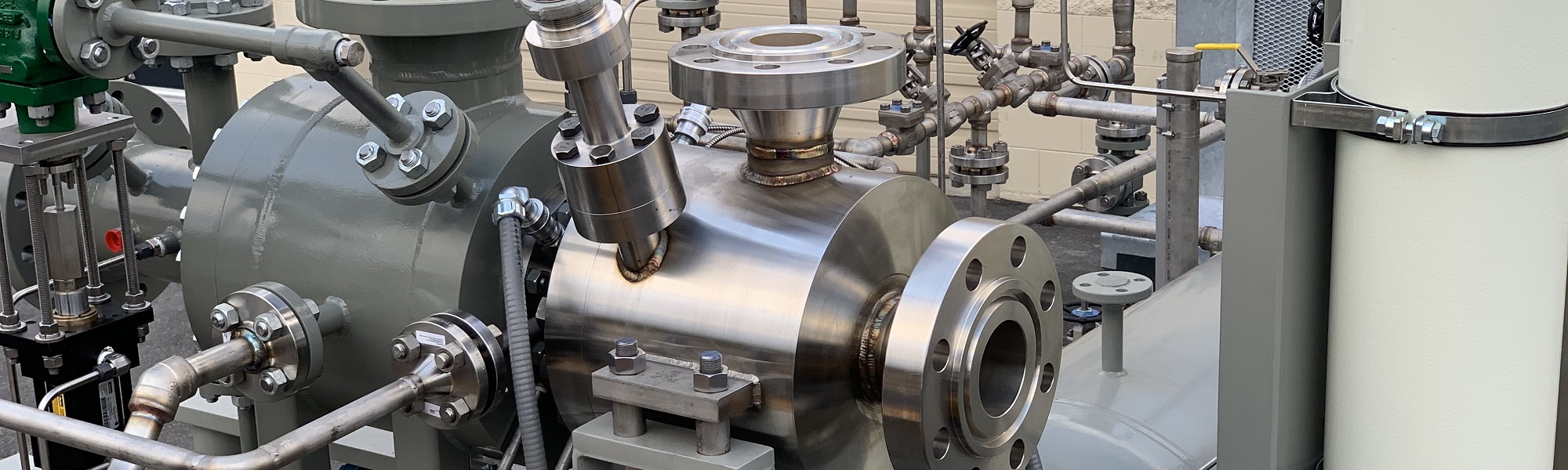

New Packaged Equipment

Supplied as either a bare machine or a skidded package, Blair Engineering can support your new unit turbo-expander needs. Our standardized oil bearing skidded package designs offer competitive pricing and delivery for cryogenic gas plants ranging from 25 MMSCFD to 350 MMSCFD. If a custom packaged design and machine is desired, the flow range Blair Engineering can provide is virtually unlimited, from 5 MMSCFD to 1 BCFD. With custom designed aerodynamics for every job, we routinely exceed customers process performance requirements as well as the low operating noise level that is expected from modern turbomachinery design. Magnetic bearing (AMB) machines are also available if desired. Whether you are looking to upgrade an existing facility or are building a new facility, Blair Engineering can support your new equipment needs. For more information, or to request a quote, please contact Blair Engineering at (805) 457-8800 or by email at Contact@Blair-Engineering.com.

System Features

Our API 610/614 support system design utilizes magnetic coupled pumps as standard, eliminating the operational issues associated with other high pressure mechanical sealed pumps. As standard, system piping is stainless steel for cleanliness, which also eliminates the need to perform a complete flush of the lube system during commissioning. IEEE-841 motors are used for the lube oil fan and pump drives as standard. ASME rated vertical cooler, simplex seal gas filter housing, duplex lube oil filter housing, and lube oil reservoir are also standard.

Control System

Blair Engineering’s standard turbo-expander package incorporates an on skid control system using an Allen Bradley PanelView 1500 plus 7 HMI with a CompactLogix PLC. Industry standard Rosemount pressure transmitters are used and are indicating to eliminate the need for additional gauges. While other area classifications are available, Blair Engineering’s standard package meets or exceeds Class 1 Div 2 Group C, D specification.

Machine Features

Designed per API-617 and equipped with a variable inlet guide vane mechanism, Blair Engineering’s turbo-expander frames operate efficiently across a wide range of conditions. A fisher actuator with an electronic HART positioner is supplied for precise inlet guide vane control and ease of field calibration. As per standard, a thrust balance valve is included on all turbo-expander designs. Impellers are milled in house from billet material, and are custom designed per application. Our typical compressor aerodynamic designs are high back sweep type, which gives the widest operating range and highest performance. Each impeller design is overspeed tested and precision balanced for years of trouble free operation.

Bearings are manufactured in house and are combination radial and thrust bearing with embedded dual element RTD for accurate bearing temperature measurement. Blair Engineering turboexpanders use a stiff shaft design, without rotor criticals, to allow for operation at any speed without mechanical risk to the rotor parts.

Bare Units

Available as a bolt-in replacement for an existing machine or for the EPC to integrate into their modular plant design a bare unit can sometimes be the best option. At Blair Engineering, we have pre-engineered bolt-in replacement units for common existing frame machines. If a redesign is not feasible, then a bolt-in replacement machine can be a good option to increase plant throughput.