Centrifugal Compressors

We have a unique approach to high speed integral geared cryogenic compression, and can supply API 610/614/617 compliant packages when required. With up to three stages mounted on a single gearbox, Blair Engineering’s custom design approach provides high flexibility and efficiency for your process compression needs. Unlike other manufacturers, Blair Engineering also designs and manufactures our own gearboxes which improves delivery, cost as well as long term cost of ownership through reduced spare part pricing.

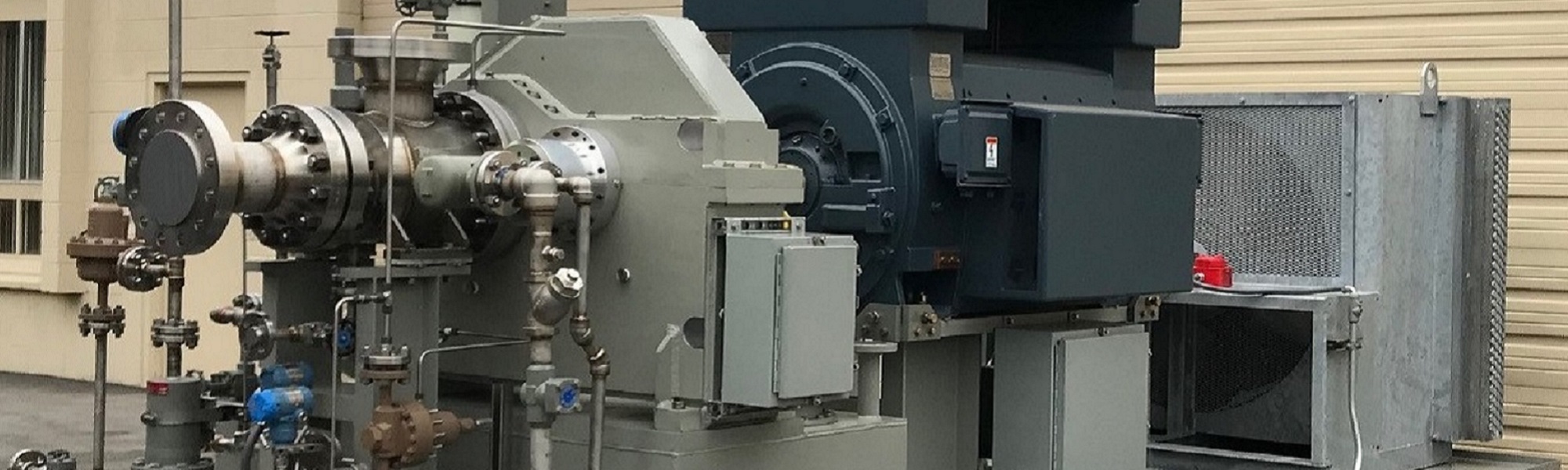

Skidded Packages

Our in-house designed and manufactured support systems are robust, with a design life minimum of 25 years. Lube systems consist of heavy wall seamless pipe welded per B31.3 as a minimum standard, stainless steel butt weld connections downstream of the filter assembly. These systems are API 610/614 compliant when required, or can be manufactured to our base standard which just has a handful of component changes to save cost. Duplexing lube filters are standard, utilizing industrial components for a long service life. Our control systems utilize Allen Bradley PLC's as standard, with Nema 4 junction boxes. Contact Blair Engineering today to discuss the needs for your latest project.

Applications

As a well-rounded supplier of custom process compression, we can supply hazardous area units with combustable process fluids as well as industrial safe area machines. We utilize varius shaft sealing types; DGS, tandem DGS, labyrinth and wet seals. On-skid PLC controls on higher specification units are typical or we can supply packages with instruments wired to on-skid junction boxes to keep capital costs low. With several in house designed gearbox frames, our scope of supply spans units from under 100 HP up to 10,000 HP.

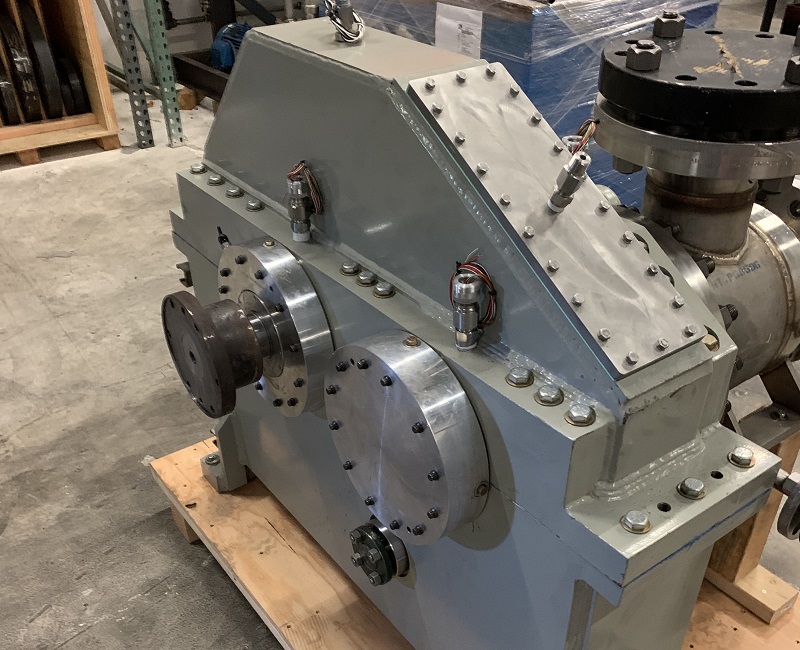

Gearbox

The core of an integral geared compressor is the gearbox, which is why at Blair Engineering we design and manufacture our own speed increaser parallel shaft units. Most units employ a stiff shaft design which allows the use of a VFD with a wide speed range when required. Bearings are also designed and manufactured at Blair Engineering, tapered land and tilting pad types are both commonly used for both radial and axial bearings. Gearsets are manufactured to AGMA 11 or better standards, here in the USA. By controlling the design and manufacture of the gearbox, we can provide less expensive capital spares and an overall higher level of service for the machine than our competitors.

Design

Our in-house engineered integrally-geared compressors utilize high effiency impeller designs for high performance and long life. Our gearbox designs allow for VFD motor control, which widens the operating range of the compressor significantly. High backsweep and near radial compressor designs are both available, to either maximize efficiency or to minimize the number of stages and cost.